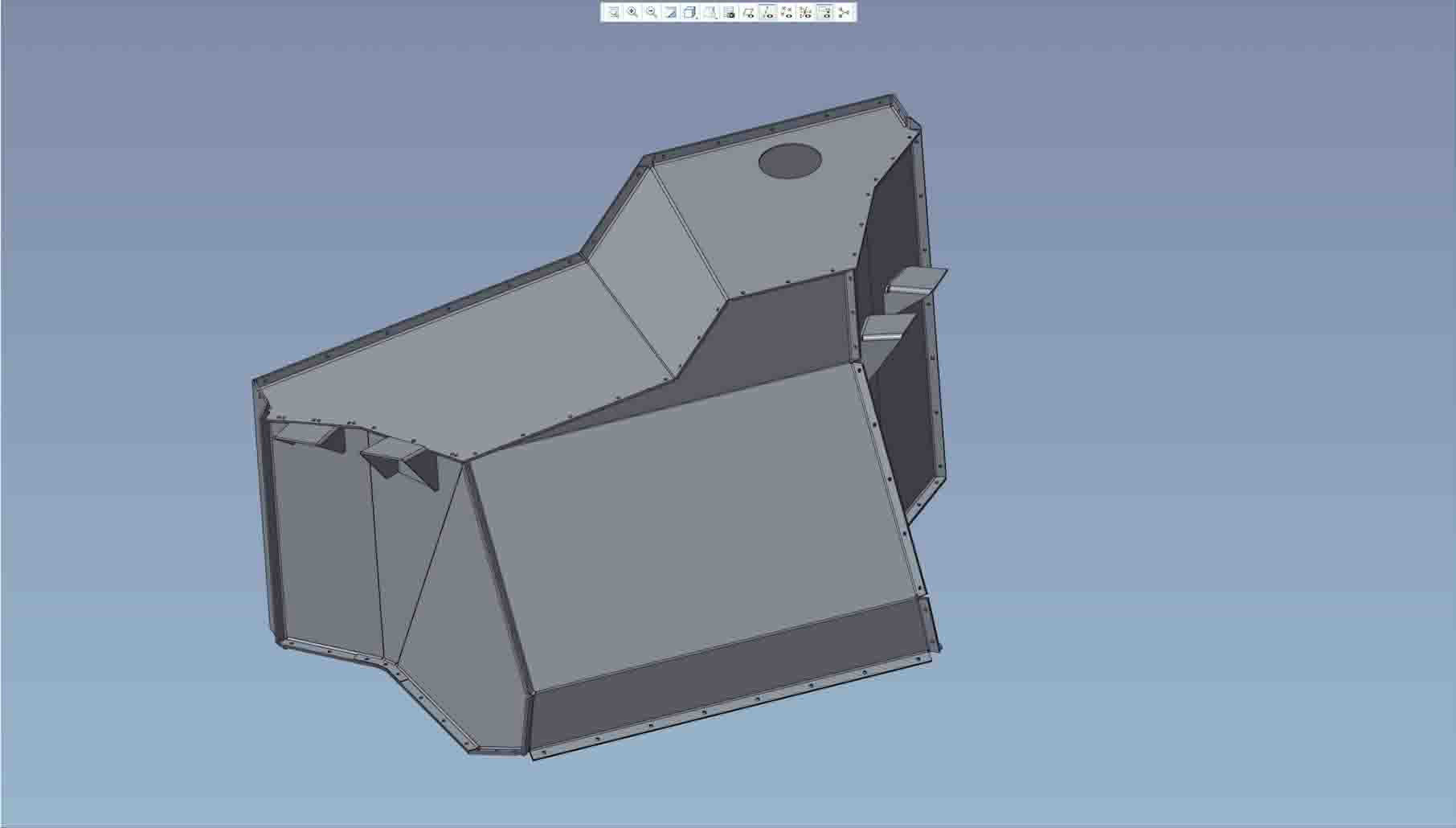

Metal stamping and sheet metal fabrication services

For customers who demand metal mechanical parts with a high degree of technical expertise and quality, we are equipped with laser cutting machines for sheets and tubes, punch presses, process cranes, hydraulic presses, CNC press brakes, plate roller, tube bending machine, welding solutions (MIG, TIG, MAG, spot and stud), machining workshop, powder coating and liquid painting lines. We will provide you the complete solution, from project design to final product. We are ISO 9001:2015 and IATF 16949:2016 certified.

Please contact us for more information about t-pieces, connectors, heatsinks and stamped parts.

Product Prototyping

For customers who seek engineering support in their product development during prototype stages.

Special projects in design and architecture

For customers who employ the noblesse of metal in their projects and whose final products demand aesthetical and sophisticated finishing. Modular stainless steel cabinets fabrication and customized projects.

Our History

35 years of solid and responsible growth, looking at the future and beyond.

Founded in the South Area of São Paulo city, initially named Magna Iluminação e Produtos Eletrônicos Ltda. manufacturing heatsinks and stamped parts.

Acquisition of headquarters (340 m²). Renamed Unimagna Metalúrgica Ltda. in order to reflect new activities incoporated in the company core business, namely sheet metal services.

Transferred to new plant in Bragança Paulista, São Paulo state, built area 1.000 m².

Expansion of the plant, focusing in processes improvement through modern machinery and qualification of professionals in the region.

New expansion totalizing 7.200 m² of built area. Investment in machinery, coating and painting lines, consolidating the company core business as a provider of complete solutions in sheet metal services.

Adoption of lean manufacturing practices. Added new area equipped with two production cranes aiming at medium metal fabrication markets, total built area 12.900 m².

Start of operation of photovoltaic plant for self-consumption. IATF 16949: 2016 certification.

Mission

Create economical, human and technological value in a consistent way, always complying with moral, ethical and legal principles.

Vision

To be a global company by adding technology and cutting edge knowledge to our products and processes, contributing to our country development.

Values

Respect Union Dedication Creativity

Surpass Flexibility Agilility Simplicity

Quality Policy

UNIMAGNA METALÚRGICA LTDA. is a Brazilian metal fabrication business. We aim at quality in all our products and services by committing with:

- Maintenance of a Quality Management System following ISO 9001 and e IATF 16.949 standards.

- Continuous improvement of the Quality Management System, targeting our customers satisfaction.

- Fulfillment of applicable requirements.

- Establishment and monitoring of the quality targets.

Environmental Policy

Take our responsibility in the planet preservation through conscious use of resources, elimination of sources of waste in our manufacturing processes and actions of environmental recovery and awareness.